235 hlobolisa tšepe

Tlhaloso e Khutšoanyane:

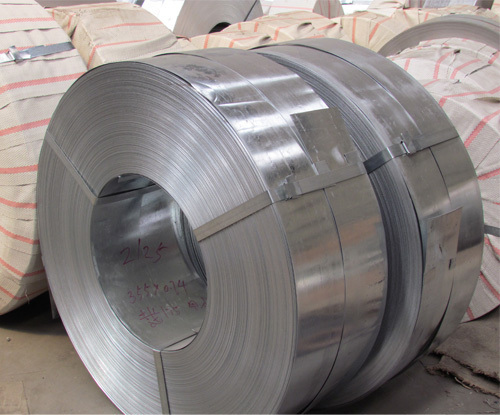

The strip tšepe ka kakaretso e fanoa ka li-coil, tse nang le melemo ea ho nepahala ho phahameng, boleng bo botle ba holim'a metsi, ho sebetsa habonolo, ho boloka thepa joalo-joalo.E tšoanang le poleiti tšepe, hlobolisa tšepe e arotsoe ka ba tloaelehileng hlobolisa tšepe le boleng bo phahameng hlobolisa tšepe ho ea ka thepa e sebelisoang;Ho ea ka mokhoa oa ho sebetsa, e arotsoe ka sekhahla se chesang se chesang le se pholileng.

Ts'ebetso ea tlhahiso ea likhoele tse kolobisitsoeng tse batang hangata ke tse latelang: ho kha → ho bilika → ho tlotsa → ho tlotsa → ho lekanya → ho kuta → ho paka.

Ts'ebetso ea likhoele tse batang: Ho qoelisoa - ho roala - ho kolobisoa - ho tlotsa ka mokhoa o ts'oanang oa boholo ba ho koloha - oli e thibelang ts'ebetso - ho lekanya le boholo - ho bentša - ho paka.

Hot strip rolling process: futhumatsang sebopi - dephosphorization mochini - roughing mill - dephosphorization mochini - finishing leloala - holim'a boleng ba tlhahlobo sesebelisoa - layer cooling - coiler - baler - ho tšoaea mochini - rolling stock slab

Ts'ebetso ea tlhahiso e chesang ea rolled: pele, phahamisa mocheso ka sebōping sa ho futhumatsa ho mocheso o hlokahalang, ebe o kenya mochine o hlabang oa dephosphorization ka tafole ea rolara ho tšoara tekanyo ea tšepe ea oxide e hlahisoang ke letlapa, ebe u kenya yuniti ea ho roala roughing ho theola. bophara le botenya ba hlobolisa, 'me joale li tsamaise ho tloha tafoleng rolara ho qetela dephosphorization mochine ho tšoara tšepe oxide sekala generated ka holim'a hlobolisa, Kena finishing rola yuniti bakeng sa phuthoa nepahetseng haholoanyane ea botenya le bophara ba. tšepe e hlobotseng.Ka mor'a hore mocheso holim'a tšepe hlobolisa ka tieo laoloa ke rolara tafole ka lera tsidifatso pele coiling, e kena ka coiler ho fetoha tšepe khoele.Qetellong, e bokelloa, e fafatsoe ebe e romeloa sebakeng sa polokelo ea li-coil bakeng sa polokelo le ho paka.